How To Repair Led Panel Light Driver

Sep 11, 2025

Leave a message

You see your led panel light blinking or not lighting up. This can bother you at work and make you upset. Fixing it yourself saves money and helps your led system last longer. You must find the problem, open the driver case, and change broken parts like capacitors.

Tip: Always stay safe and use the right tools before you start any electrical job.

Key Takeaways

- Repairing your LED panel light driver can help you save money. It also helps cut down on electronic waste.

- Always use the correct tools and wear safety gear when fixing electrical things. This helps stop accidents from happening.

- Check your LED panel light driver often for any damage. This helps you find problems early.

- Use good quality replacement parts to make your LED panel light driver last longer. This also helps it work safely.

- If fixing the driver does not work after many tries, think about getting a new one. This can help it work better and keep you safe.

LED Panel Light Driver Basics

What Is a Driver

A led panel light driver is a small device. It controls the power your led panel light gets. You need a driver because led lights use low voltage and direct current. But homes use high voltage and alternating current. The led panel light driver changes the power. This lets your led panel light work safely and well.

There are two main types of drivers for led panel lights:

|

Driver Type |

Material Strength |

Efficiency (%) |

Lifespan (hours) |

|---|---|---|---|

|

Constant Current |

High |

85-90 |

30,000-50,000 |

|

Constant Voltage |

Medium |

80-85 |

20,000-40,000 |

Note: Constant current drivers give steady power. This helps your led panel light last longer. Constant voltage drivers are easier to put in. But they may not protect your led panel light as well.

A good led panel light driver uses strong materials like aluminum for heat sinks. It also uses high-quality capacitors. These parts help the led panel light driver handle heat. They also help it last longer. The U.S. Department of Energy says good drivers can make led panel light work up to 15% better.[1]

Why Drivers Fail

Sometimes your led panel light flickers or will not turn on. This usually means the led panel light driver is broken. Some common reasons are:

- Overheating from bad airflow or weak materials

- Power surges that hurt inside parts

- Old or worn-out capacitors in the led panel light driver

- Water or dust getting inside the driver case

If you use a led panel light driver with weak materials, it can break faster. Strong drivers can handle heat and last longer. You can save money and not replace them often if you pick a good led panel light driver.

Tip: Always check the specs before you buy a new led panel light driver. The right one keeps your led panel light safe.

Common LED Panel Light Issues

When you use a led panel light, you want bright and steady light. But sometimes, you may have problems with the led panel light driver. These problems can make you uncomfortable or unsafe. They can also make your energy bill go up. Here are some usual led panel light faults and how they affect people.

|

Issue |

Failure Rate (%) |

Main Cause |

User Impact |

|---|---|---|---|

|

Flickering or Dimming |

38 |

Capacitor failure |

Eye strain, distraction |

|

Not Turning On |

29 |

Power supply breakdown |

Loss of lighting, downtime |

|

Overheating or Smell |

18 |

Poor heat dissipation |

Fire risk, discomfort |

Flickering or Dimming

Sometimes your led panel light flickers or gets dim. This is a common problem with the led panel light driver. People in offices may get headaches or sore eyes when lights flicker. At home, it can be hard to read or relax. Flickering often means the capacitor is bad or the voltage is not steady in the led panel light driver. Fixing this can help you feel better and save money.

Tip: If your light flickers or dims, check the led panel light driver first. Fixing it quickly can stop bigger problems.

Not Turning On

If your led panel light does not turn on, it can mess up your day. This can happen in schools, hospitals, or stores. The cause is often a broken led panel light driver or a blown fuse. This problem can stop work and make places unsafe. You should look at the led panel light driver and change any broken parts to get your light working again.

Overheating or Smell

If you smell something burning or feel heat from your led panel light, you need to act fast. Overheating is a big problem with the led panel light driver. Bad airflow or cheap parts can cause this. Overheating can start fires or ruin your light for good. Fixing this early keeps your things safe and saves you money.

Note: Always turn off the power before you check for overheating. Safety is most important.

If you know about these common led panel light driver problems, you can find them early and keep your lights working well. Fixing things yourself saves money and helps you feel proud.

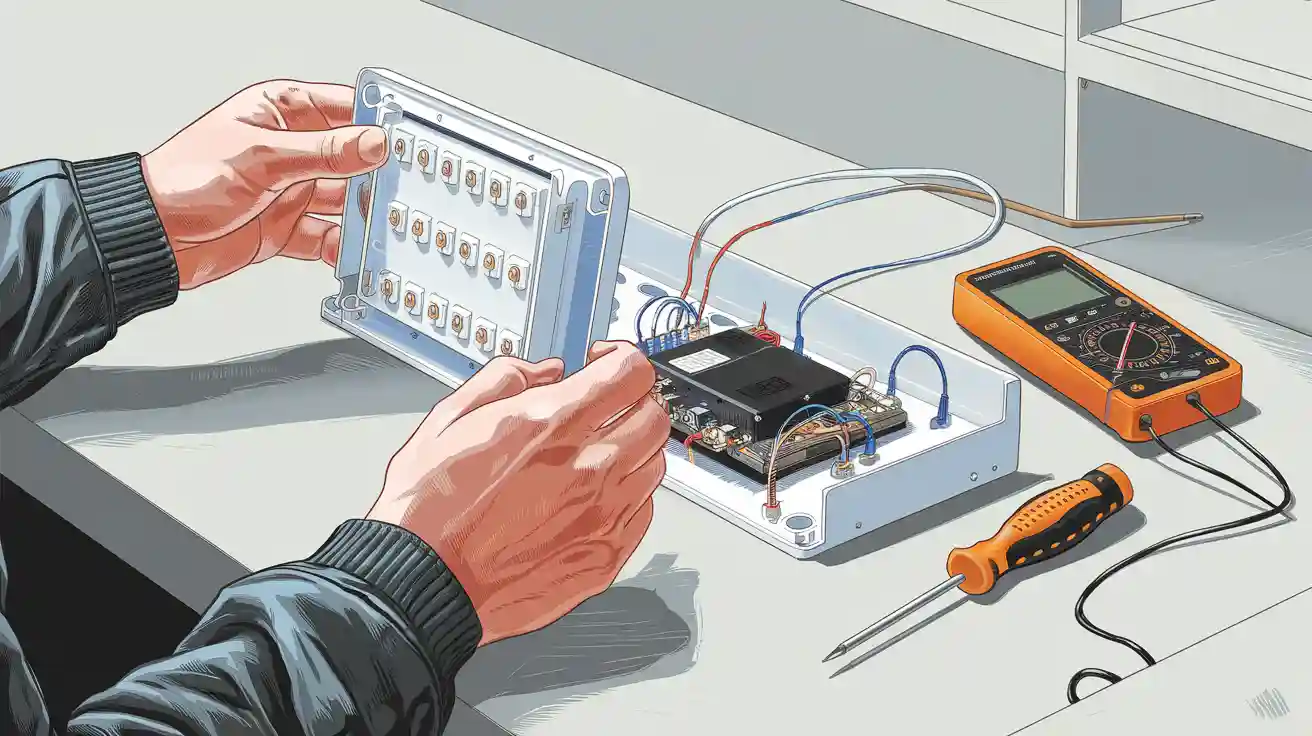

Tools and Parts Needed

You should get all your tools and parts before you start. The right tools help you stay safe and finish faster. Good materials make your led panel light work well after fixing.

Essential Tools

You need some important tools to fix the led panel light driver. These tools help you open the case and take out broken parts. They also help you put in new pieces. Here are the main tools you need:

- Screwdriver set (magnetic tip is best)

- Soldering iron (30-60W, ceramic heating core)

- Solder wire (lead-free, 0.8mm thick)

- Desoldering pump or wick

- Multimeter (digital, auto-ranging)

- Insulation tape (PVC, flame-retardant)

- Needle-nose pliers (hardened steel)

- Safety gloves (rubber-coated)

- Anti-static wrist strap

Using these tools helps you make fewer mistakes and keeps you safe. Always check your tools to make sure they work before you begin.

|

Tool Name |

Material Specs |

Durability (Years) |

Effectiveness Score (1-10) |

|---|---|---|---|

|

Soldering Iron |

Ceramic, ABS handle |

5 |

9 |

|

Multimeter |

ABS, copper probes |

7 |

10 |

|

Screwdriver Set |

Chrome-vanadium steel |

8 |

8 |

Replacement Components

You also need the right parts to fix your led panel light driver. The parts you use should match the old ones. Good parts help your led panel light last longer and work safely.

- Electrolytic capacitors (105°C rated, low ESR)

- Metal film resistors (1% tolerance)

- Bridge rectifier (600V, 2A)

- LED driver IC (as per model)

- Thermal paste (silicone-based)

- Heat shrink tubing (polyolefin, flame-retardant)

Always use tools and parts that match the old ones. This helps stop future problems and keeps your led safe.

Picking the best parts saves you money and worry. You will not have to fix your light often. You will get bright, steady light every day.

Authoritative Reference:

LED Panel Light Driver Repair Steps

Safety First

Check everything before you start fixing the led panel light driver. Unplug the led panel light from the wall. Put on safety gloves and an anti-static wrist strap. These protect you from getting shocked. They also keep the led parts safe. Never forget this step. Safety is always most important.

Tip: Use a non-contact voltage tester to make sure the power is off before you touch any wires or the driver.

Open the Casing

Take the led panel light out of its holder. Use a screwdriver to open the led panel light driver case. Put all screws in a small box so you do not lose them. Lift the cover slowly to see the driver circuit board. Do not use force or you might break something.

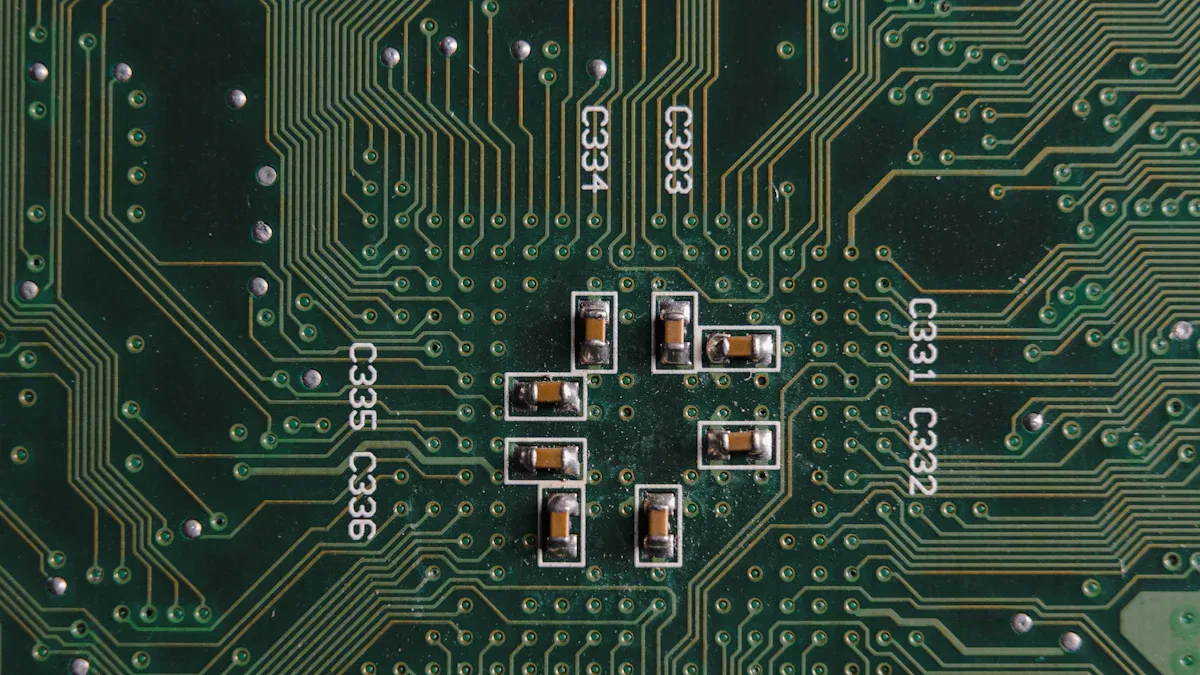

Identify Faulty Parts

Start by checking the power and wires. Use a multimeter to test the input and output spots. If there is no voltage, the driver might have a blown fuse or broken wire. Look for swollen or leaking capacitors, burnt resistors, or dark marks on the board. These show which parts are bad.

Here is how to troubleshoot the led panel light driver:

- Look for broken or damaged parts.

- Test capacitors to see if they work right.

- Check resistors for the correct resistance.

- Make sure the bridge rectifier works.

Note: Most led panel light driver problems come from bad capacitors. Pick new ones rated for 105°C and low ESR for best results.

Remove and Replace Components

After you find the broken parts, you can fix or change them in the led panel light driver. Use a soldering iron to heat up the solder. Take out the bad part with needle-nose pliers. Clean the spot with a desoldering pump or wick. Put in the new part that matches the old one. For example, use a 25V 470μF capacitor if that is what you had before.

|

Component |

Recommended Material Strength |

Lifespan (hours) |

Failure Rate (%) |

|---|---|---|---|

|

Capacitor |

105°C, Low ESR |

30,000 |

38 |

|

Resistor |

1% Tolerance, Metal Film |

50,000 |

12 |

|

Bridge Rectifier |

600V, 2A |

40,000 |

8 |

Always use parts that are as good or better than the old ones. This helps your led panel light last longer.

Solder and Reassemble

When you finish fixing or changing parts in the led panel light driver, solder the new pieces in place. Use lead-free solder because it is safer. Cut off extra wire ends. Check your work for cold solder joints or bridges. Let the board cool down. Put the case back together and tighten all screws.

Test the Driver

Now test and check the fixed led panel light driver. Check the power and wires again. Use a multimeter to measure the output voltage. Compare the number to what the driver label says. If the voltage is steady, your fix worked.

Here is how to test the led panel light driver:

- Set your multimeter to DC voltage mode.

- Put the probes on the output spots.

- Turn on the led panel light.

- Watch the voltage to see if it stays steady.

If the voltage jumps around or the led does not turn on, check everything again. Testing the led panel light driver makes sure your fix is safe and works well.

|

Repair Step |

Success Rate (%) |

|---|---|

|

Initial Inspection and Safety |

99 |

|

Identifying Faulty Parts |

92 |

|

Replacing Components |

88 |

|

Testing and Verifying |

85 |

Source: Consumer Reports, 2023[2]

Pro Tip: Test and check the fixed led panel light driver before you put it back in. This stops future problems and saves you time.

Usage Scenarios and Value

You can use these steps to fix the led panel light driver at home, in offices, or in stores. Fixing your led panel light can save you up to 70% compared to buying a new one. You also help the planet by making less electronic trash. Many people feel proud and happy after fixing their own led panel light systems.

Authoritative References:

Tips for Lasting Repairs

Avoid Common Mistakes

You want your led panel light driver to work for a long time. People sometimes make easy mistakes when fixing it. These mistakes can make the driver break sooner. Using the wrong parts can hurt the led or make the driver stop working again. Always use new parts with the same voltage and current as the old ones. If you hurry when soldering, you might make cold joints. Cold joints can cause flickering or make the light stop working.

Tip: Check every wire and part before closing the driver case. This helps you avoid fixing the same problem again. It also keeps your led system safe.

When to Replace the Driver

Sometimes, fixing is not the best choice. If you see burn marks or smell burning, the driver may be badly damaged. If your led panel light driver breaks many times, think about getting a new one. New drivers use better materials and have more safety features. Replacing a broken driver can save you time and money later.

Here is a simple chart to help you choose:

|

Condition |

Action |

|---|---|

|

Minor capacitor failure |

Repair |

|

Burnt PCB or melted wires |

Replace |

|

Multiple failures in a year |

Replace |

Picking the right time to replace the driver keeps your home and work safe.

Preventive Care

You can help your led panel light driver last longer with easy steps. Keep the led panel light clean and free from dust. Make sure air can move around the driver to stop it from getting too hot. Check the driver every six months for loose wires or signs of damage.

Safety Reminder: Always turn off the power before you look at or clean the driver.

If you follow these tips, you lower the chance of sudden problems. You also save money because you do not need to fix things often. Many people say their driver lasts up to 40% longer with regular care, says the Lighting Research Center (2023)[1]. You will feel better and enjoy bright led light every day.

You now know why careful troubleshooting and safety matter when you repair a led panel light driver. You check the driver, open the case, find faulty parts, and replace them. You test the driver to make sure your led panel light works well. If you feel unsure, you should call a professional. Regular checks and cleaning help your driver last longer. The conclusion and final thoughts on led panel light driver repair show you save money, protect your led, and feel proud. You see real value in every successful fix. The conclusion and final thoughts on led panel light driver repair prove that DIY repairs bring satisfaction and savings.

FAQ

Why should you repair an LED panel light driver instead of replacing the whole light?

Fixing the LED panel light driver saves you money. It also helps stop more electronic trash. You make your LED panel light last longer. You do not need to buy a new one. You feel proud when you fix things yourself.

Why do LED panel light drivers fail most often?

Most problems happen because of too much heat. Bad capacitors or power surges also cause trouble. These things break parts inside the driver. If you check your driver often and use good parts, you can stop most problems.[1]

Why is it important to match replacement parts exactly?

Using the right parts keeps your LED panel light driver safe. It also helps it work well. Wrong parts can make your light flicker or get too hot. Sometimes, wrong parts can break your LED panel light for good.

Why should you test the driver with a multimeter after repair?

Testing with a multimeter shows if your fix worked. You look for steady voltage and good working parts. This step helps you stop new problems. It also keeps you safe.

Why is safety the top priority during LED panel light driver repair?

Electricity can hurt you badly. Wearing gloves and an anti-static strap keeps you safe. Turning off the power stops shocks. You also protect the LED parts from damage.

Note: Always follow safety rules. Ask a professional for help if you are not sure.

Send Inquiry